USD 49 000

From

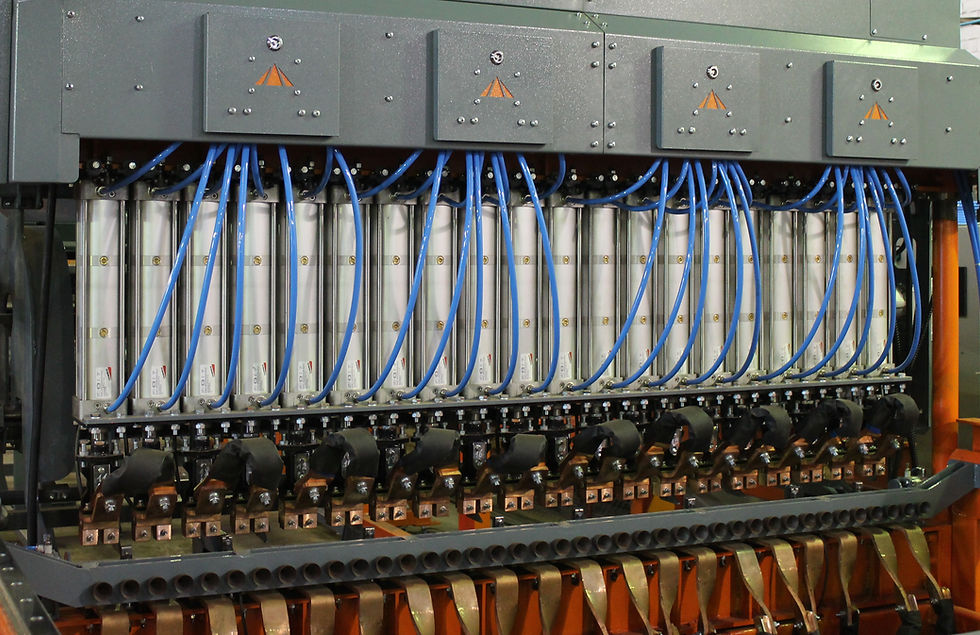

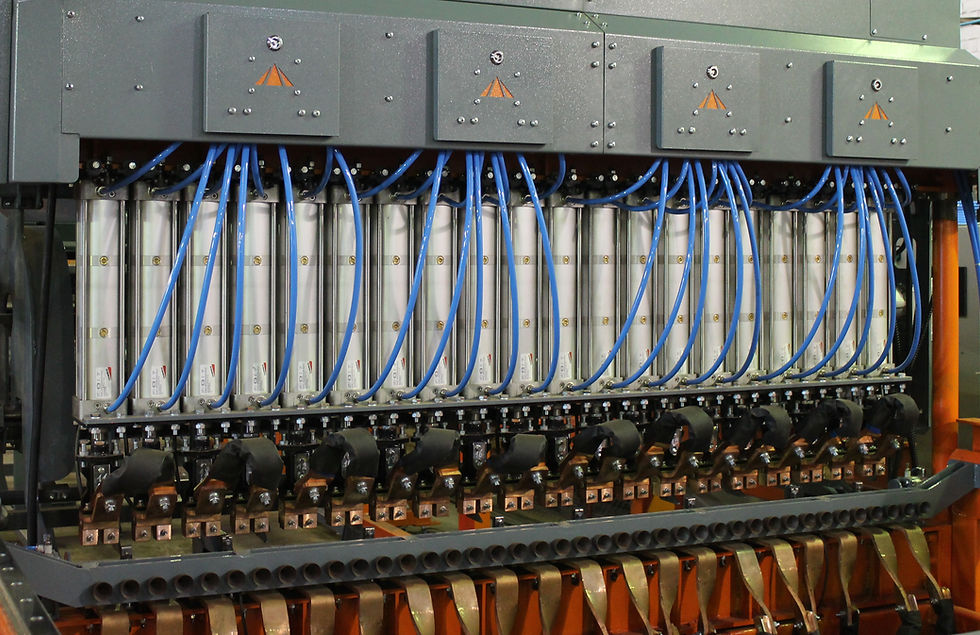

Semi-automatic welding machine for mesh production

Rosstroytech offers semi-automatic welding line WP series with great performance.

How it works

Operator sets up appropriate technical parameters via control panel, and makes general adjustments of the equipment before welding. The machine uses longitudinal and transverse pre-cutted in size rods that loaded to the appropriate bunkers. Automatic feeder drops the transverse rods from the bunker into welding zone; the longitudinal rods are loaded manually. Automatic welding in place of intersections is performed simultaneously.

Basic features

The standard version of WP series equipped with the transverse rods feed module. To improve performance additional modules are available, such as feeding of longitudinal rods module, hydraulic guillotine, packaging unit.

Longitudinal feed unit

The unit allows loading new rods during the actual process of welding mesh, reducing downtime & increasing the productivity 1.5-2 times average. Operator loading the longitudinal rods manually into the individual seizure. The frame moves the longitudinal rods to the welding zone. Sensors exclude the possibility of defective manufacturing mesh.

Longitudinal transfer unit

Longitudinal transfer module within the welding zone allows making a mesh with variable step. Moving the mesh strictly forward by rack provides an ideal rectangular shape cells.

Packaging unit

Packaging unit removes the welded mesh from the welding machine. When the production is complete, the leafs drop down the ready mesh in a stack. If necessary, the unit can be equipped with manipulator, and turn over every second mesh.

Request for

commercial offer

& technical specs

+7 (929) 677-19-34

info@rus-bt.com

Call now: +7 (929) 677-19-34